The addition of a new top-of-the-range model, the Jaguar 990, is at the forefront of a number of updates and new features available across the Jaguar 900 and 800 ranges for 2020. These include the adoption of the latest Cebis touchscreen based control concept across the whole Jaguar range, plus a change to more powerful Stage 5 engines for the Jaguar 900, a new additive system and a 42-knife chopping cylinder, plus the availability of dynamic steering.

For 2020, all Jaguar 900 machines will make the move to Stage 5 engines developing more power and providing an increase in torque. The Jaguar 800 range will continue to be powered by Stage 4 compliant engines, with the move to Stage 5 coming in time for maize harvest.

Topping the Jaguar 900 range of forage harvesters, the new Jaguar 990 is powered by a 925hp MAN engine. The MAN V12 has a displacement of 24 litres and an 850hp version will also be used in the Jaguar 980. The Jaguar 970 moves to a new MAN D4276 straight six, which develops 790hp from its displacement of some 16 litres. With a displacement of almost 3 litres per cylinder this promises a stable power curve with sustained torque, giving the Jaguar 970 what Claas claims are the best figures in its class with regard to fuel consumption per tonne of harvested material. The power output of the Jaguar 960 and 940 models has also increased.

Touch screen Cebis

The Jaguar 900 ranges will now come with the new touch screen CEBIS terminal, and Claas claims that this gives the operator fast and easy access to all the machine functions. Again the Jaguar 800 will see this feature in the autumn.

Depending on individual preference, the operator has four options for setting up and adjusting the Jaguar:

• A simple tap on the touchscreen and the new Cebis terminal reacts by providing direct access to all machine functions.

• Seven settings can be programmed as favourites and accessed by rocker switches on the CMOTION control lever, which is now standard on all machines.

• Cebis rotary/push switch and pushbutton

• Direct adjustment via switches in the armrest

A big benefit for operators when using the new armrest and CMOTION control lever is that it will be possible to adjust the machine on the move from the joystick using the new favourite settings.

Another new feature for 2020 is the availability of dynamic steering on the Jaguar 900, allowing the operator to reduce the number of turns to go from lock to lock. At up to 10 km/h, the operator only needs 1¼ turns of the wheel to go from full left lock to full right. From 10 to 20 km/h, the steering wheel turns required are increased dynamically. From 20 km/h, for the sake of safe driving at higher speeds, the full number of steering wheel turns is available again. Dynamic steering is activated in Cebis and it’s possible to adjust the number of steering wheel turns required at any time.

The Cemos Automatic system will now also be available on the Jaguar 900. The system claims to maintain a target engine speed and therefore crop flow or forward speed while adjusting the engine horsepower to what is required. Claas claims that this offers the operator the potential to increase productivity and reduce fuel use.

Ground drive, tyres and drum

The new Jaguar 800 series will also benefit from an updated hydrostatic ground drive giving the machine more pulling power both in the field and on the road. There is also a new optional rear tyre, the 620/55 R26 offers an increased footprint and improved traction due its construction tread design over the previous 600/55 R26.5 rear tyres.

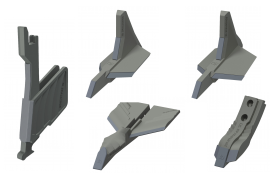

A new option for Jaguar 990/980/970 models is the 42-blade V-Max chopping cylinder, which gives a cutting frequency of 25,200 cuts/min. Claas claims that the new 42-blade V-Max drum is designed to deliver particularly high throughput, providing top-quality chopped material at chop lengths from 3.5 to 12.5 mm. Where a longer chop length is required in grass or for Shredlage, the chopping cylinder can be run with just 14 blades fitted.

A new hydraulic pre-compression system is also standard in all Jaguar 900 models. Acting on pre-programmed control characteristics, hydraulic rams with pressure reservoirs automatically adjust the pre-compression pressure applied, in order to accommodate different crops and changes in the thickness of the crop flow.

The sealing of the chopping cylinder sharpening system has been improved to help reduce dirt ingress and noise. The service life of the chopping cylinder bearings has been extended and a flat-face coupling makes for easier maintenance of the feeder housing and knife drum housing.

As an option, dry matter content value can be determined using the latest near infrared sensor (NIR), which can then be used as a reference for setting the chop length and the amount of additive required. The NIR sensor can also be used to determine constituents such as starch and protein levels which vary depending on the crop concerned.